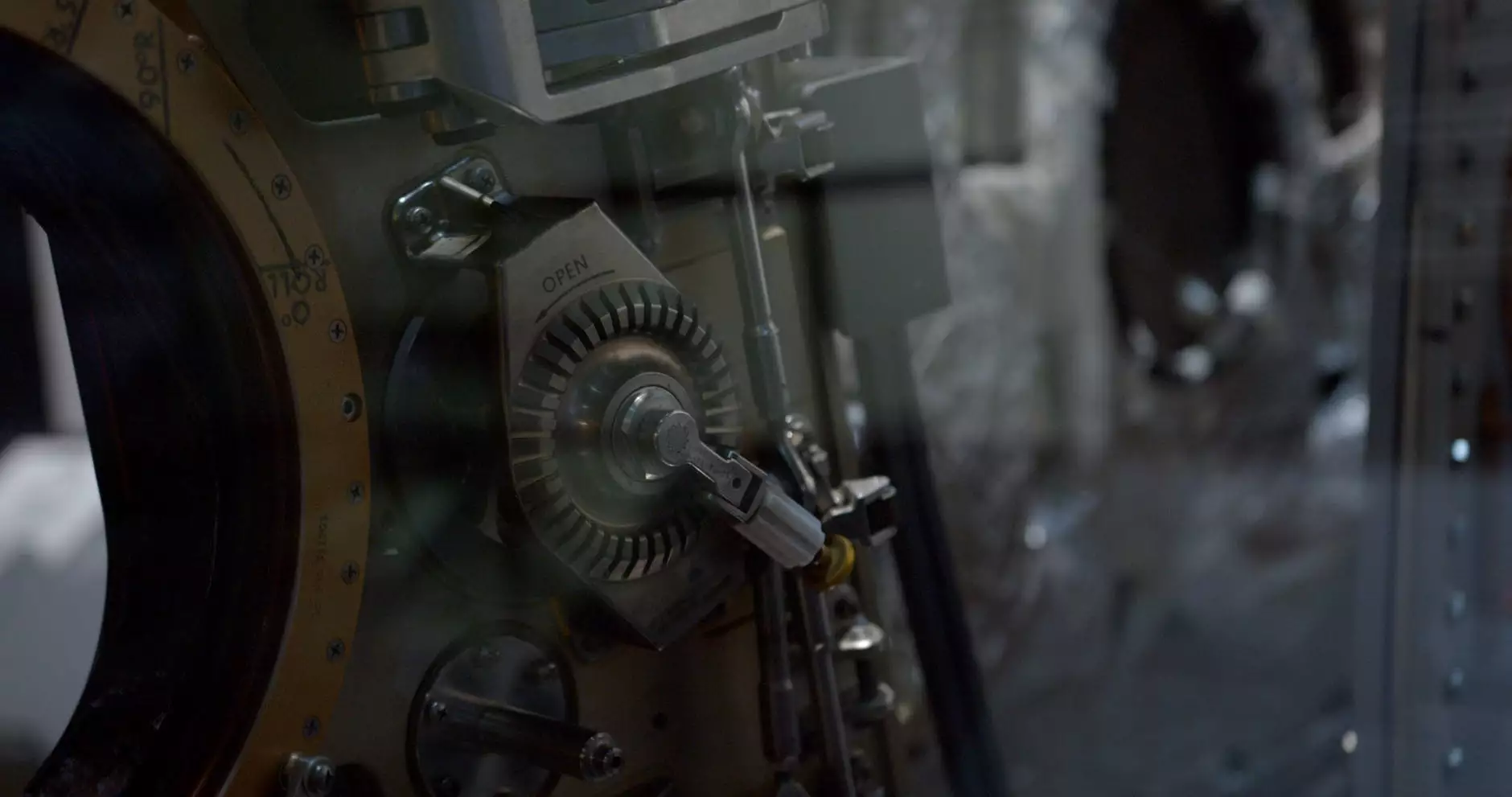

Understanding Torque Converter Automatic Systems

In the world of automotive engineering, the torque converter automatic system stands out as one of the most significant advancements in vehicle technology. It serves a crucial role in the functioning of automatic transmissions, enabling smoother gear shifts and enhancing overall vehicle performance. This article delves deep into the intricacies of torque converters, their types, functionalities, and the many advantages they provide.

What is a Torque Converter?

A torque converter is a type of fluid coupling specifically designed to transfer rotating power from an engine to a transmission. It allows the engine to spin independently of the wheels, facilitating smooth starts and providing additional power when needed. It effectively replaces the mechanical clutch found in manual transmissions, making driving more accessible and enjoyable for all drivers.

Components of a Torque Converter

The torque converter is comprised of several critical components that work together to ensure optimal performance:

- Impeller: This is the part connected to the engine. As the engine spins, it causes the impeller to rotate, generating fluid motion.

- Turbine: Connected to the transmission, the turbine is driven by the fluid from the impeller. When fluid hits the turbine blades, it spins and transfers power to the car's drive wheels.

- Stator: This component redirects the fluid coming from the turbine before it returns to the impeller, improving efficiency.

- Converter Housing: The outer casing that holds all the components together while enabling the fluid to flow freely within.

- Lock-Up Clutch: This is an optional feature found in modern torque converters that allows for a direct connection between the engine and transmission at higher speeds, improving fuel efficiency.

How Does a Torque Converter Work?

The operation of a torque converter automatic is both complex and fascinating. Here's a step-by-step breakdown of how it works:

- Engine Power Generation: When you start your vehicle, the engine begins to produce power that spins the impeller.

- Fluid Motion: The spinning impeller creates centrifugal force that moves transmission fluid outwards, generating fluid circulation.

- Power Transfer: As the fluid flows toward the turbine, it pushes against the turbine blades, causing it to spin and transmit power to the vehicle’s wheels.

- Fluid Recirculation: Once the turbine spins, the fluid returns to the impeller via the stator, where it’s re-energized and sent back out to repeat the cycle.

- Lock-Up Mechanism Activation: Under specific conditions, such as highway cruising, the lock-up clutch engages, connecting the engine directly to the transmission to eliminate slippage and improve efficiency.

The Advantages of Torque Converter Automatics

Employing torque converter automatic systems in vehicles offers several benefits:

- Smoother Acceleration: By allowing the engine to operate independently from the wheels, torque converters provide seamless acceleration without the engine stalling.

- Improved Fuel Efficiency: With the lock-up clutch, the engine can run at lower RPMs, enhancing fuel economy during steady driving conditions.

- Enhanced Performance: Torque converters can multiply engine torque, enabling better acceleration from a standstill or during overtaking.

- Reduced Driver Fatigue: Automatic transmissions equipped with torque converters reduce the need for constant shifting, making driving less laborious, especially in heavy traffic.

Types of Torque Converters

Torque converters come in various types, each with distinct characteristics suited for different driving conditions:

- Standard Torque Converters: These are commonly used in most vehicles, balancing performance and fuel efficiency.

- High-Performance Torque Converters: Designed for sports cars or racing applications, these converters provide quicker response times and higher torque multiplication but may compromise some fuel efficiency.

- Lock-Up Torque Converters: As mentioned earlier, these converters engage a clutch to lock the turbine to the engine, which increases fuel efficiency, especially at higher speeds.

- Variable Pitch Torque Converters: These allow for adjustment of the turbine and impeller blade angles to optimize power transfer based on driving conditions.

Maintaining Your Torque Converter

Keeping your torque converter in optimal condition is essential for maintaining the overall performance of your vehicle. Here are some tips for proper maintenance:

- Check Fluid Levels: Ensure that the transmission fluid is at the proper level and of good quality. Low or contaminated fluid can lead to poor performance and premature wear.

- Monitor for Slippage: If you notice your vehicle hesitating during acceleration, it may signify torque converter slippage. Address this issue promptly to avoid further damage.

- Regular Servicing: Follow your manufacturer’s recommended service intervals for transmission fluid changes and inspections.

- Inspect for Leaks: Look for any signs of fluid leaks around the transmission or where the torque converter connects to the engine.

Common Issues with Torque Converters

While torque converters are generally reliable, they can experience problems over time. Here are some common issues to watch out for:

- Overheating: If the fluid becomes too hot due to prolonged stress or low levels, it can lead to significant component damage.

- Worn Clutch: If the lock-up clutch wears out, you may feel vibrations or hear unusual noises during acceleration.

- Fluid Contamination: Contaminated fluid can affect the hydraulic functions and lead to sluggish performance.

Choosing the Right Torque Converter for Your Vehicle

Selecting the right torque converter for your vehicle depends on various factors, including:

- Vehicle Type: Consider whether you need a torque converter for a daily driver, a towing vehicle, or a performance car.

- Driving Style: Evaluate your driving habits, whether you prioritize fuel efficiency or performance enhancement.

- Manufacturer Recommendations: Always consult with your vehicle’s manufacturer to ensure compatibility between the torque converter and your vehicle’s drivetrain.

Conclusion

The torque converter automatic system is a remarkable advancement in automotive technology that enhances driving experiences. Understanding how it functions, the advantages it provides, and proper maintenance practices can significantly improve your vehicle's performance and longevity. If you’re looking for high-quality automotive parts and supplies, visit Shenghai Auto Parts for an extensive selection that meets all your vehicle needs.

Frequently Asked Questions

What are the signs of a failing torque converter?

Common signs include slipping gears, overheating, and unusual noises when the vehicle is in gear. If you notice any of these symptoms, it’s advisable to seek professional assistance.

Can a torque converter cause transmission problems?

Yes, a malfunctioning torque converter can affect the transmission's performance, leading to shifting difficulties or contributing to transmission failure if not promptly addressed.

How often should I change the torque converter fluid?

It is recommended to change the transmission fluid every 30,000 to 60,000 miles or according to the manufacturer's guidelines to ensure longevity and optimal performance.